Getting My Aws Cwi To Work

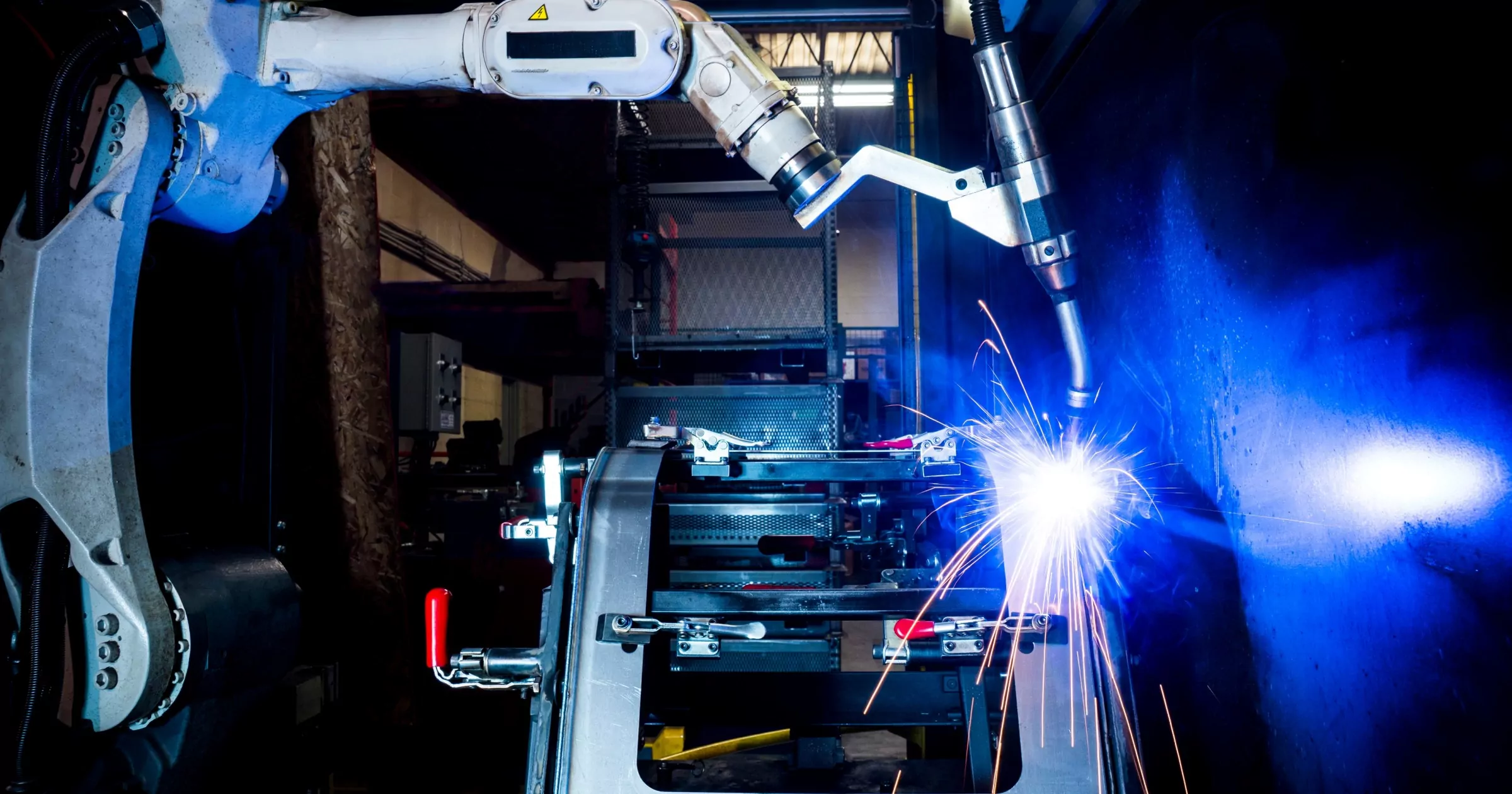

Welding top quality is straight relevant to the efficiency of the element, the life span of the component and the procedure or system in which it is made use of. Welding top quality is also tantamount to avoiding a weld failing which might be devastating or certainly unfavorable. Main Circulation Signal has a Quality assurance system that applies a Welding Assessment Program that utilizes lots of NDE techniques.

It ought to be noted that many jobs do not have requirements for utilizing qualified examiners and many companies utilize their "best" welders for this function. While this might function in some circumstances, it is certainly harmful and it has several problems, some noticeable and some not so apparent. PFS developed a program where all Welding Inspectors are certified according to ASNT SNT TC-1A and AWS QC1 Licensed Welding Inspector.

The function of All PFS welding examiners begin before the welding devices is also activated. PFS Welding Assessors are educated to examine the complying with prior to welding starts: Welder is qualified. Right WPS has actually been provided. Weld joint serves. Base product is suitably tidy before welding - Welding Inspection Service. Appropriate welding consumable has been chosen per WPS.

What Does Aws Cwi Mean?

The WPS variables are being complied with by the welder. PFS Welding Assessors then investigate all welding procedures throughout the production process to make sure that all needs are being met. The advantages of utilizing Qualified Welding Examiners: ASNT and AWS Welding assessor accreditation has actually been widely accepted by the USA and also most of the significant commercial nations worldwide.

Quality welding and extremely educated qualified welding evaluations straight influences not just the efficiency of the item yet the safety, life expectancy and reliability of the procedure that the bonded part is part of. One element of this, the Qualified Welder, is insufficient to make sure success just like any kind of process, an independent set of eyes that are educated to develop a proper training procedure along with an efficient and effective recorded surveillance system as provided by a Qualified Welding Examiner, completes the high-quality control that guarantees that the customer is provided the best possible quality constructed and recorded product.

Do not be amazed that most high-profile industries will need you to employ licensed welding inspectors to look after welding - https://pblc.me/pub/24fd7637f5417a. This is done to minimize threat in what is generally viewed as a rather risky market. An in-house qualified welding examiner will have the ability to make certain that your task is customized to all the requirements of relevant welding codes, assuring its quality

Some Known Questions About Aws Cwi.

They'll additionally start the procedure great site by conducting testing tasks like welder efficiency credentials testing and welder treatment certification screening. This typically needs some weeks to finish and require to be reviewed and accepted before the start of customers welding projects. This ensures the proficiency of those servicing your task.

Certified internal welding inspectors offer that watchful eye. They will assist you by getting rid of irregularity during the welding procedures (https://blogfreely.net/awscw1w3lding/our-nationwide-service-guarantees-top-notch-quality-compliance-and). This consequently will profit you with a quicker outcome and lowered production costs at the end of said process, allowing you to do more with the resources that you currently have

These include ductility, joint geometry, cord feed rate, arc current, arc voltage, base steel chemistry, shielding gas kind, filler steel chemistry, and tensile strength among others. It is very important that you consider the value of having a qualified welding assessor before you begin any type of task. There is an actual worth in having a skilled review your task prior to you also strike the very first arc.

Aws Cwi for Beginners

A licensed welding inspector will certainly have had years of experience which your company will be able to attract from. They will certainly have seen various pitfalls and successes and the lessons they have gained from them will certainly help your service to keep away from expensive reworks. This is why it is necessary to discover a welding company with a knowledgeable and extremely trained in-house certified welding assessor on staff.

Something failed. Wait a minute and attempt once more Try once more.

Because 1919, American Welding Society standards, services, and programs have supported the men and females of welding in the USA. Today AWS is happy to claim that our impact extends the world, and we support thousands of welding specialists worldwide. To assist our international participants, AWS contracts with organizations in countries throughout the world to facilitate certification tests.

To help welders obtain expert welding certification, we give business and customized welding training courses for various knowledge degrees and market standards and processes (Welding Inspection Agency). This technique of experience-based learning aids welders in training understand technological industry requirements and terminology while getting crucial hands-on skills. Providing this type of training means students require superb help from qualified experts.

How Aws Cwi can Save You Time, Stress, and Money.

Our weld examination procedures assist to verify the top quality and preciseness of welds, while screening methods help to recognize inconsistencies and inefficiencies. These processes incorporated influence enhanced project efficiency along welders. OXARC's varied variety of welding processes our experts can check is thorough with procedures like: Protected steel arc welding (SMAW) Gas tungsten arc welding (GTAW) Flux core arc welding (FCAW) Gas steel arc welding (GMAW) We can additionally execute certification and certification examinations on plate, pipe, stainless-steel and various other particularly requested products.

Specialist leadership, quality services and products and dedication to our market maintain OXARC providing our customers with the products and remedies they need. Our team has a direct line of communication with the specialists in welding such as Lincoln Electric, ESAB, Avesta Stainless, Stoody, Select Arc, Eutectic and Thermal Arc, making our services a perfect choice for varied sectors.

Comments on “Aws Cwi Fundamentals Explained”